|

| AAS |

Principle of Atomic Absorption Spectrometer

- A solution of metallic salt is sprayed on a flame, and fine droplets are formed.

- The thermal energy of flame the solvents in the droplets evaporate, leaving fine residue, which is converted to neutral atoms.

- The neutral atoms absorb radiation of a specific wavelength emitted by a hollow cathode lamp(HCL).

- HCL is filled with the vapour of elements which gives a specific wavelength of radiation.

- The intensity of light absorbed by neutral atoms is directly proportional to the concentration of the elements

- The intensity of radiation absorbed by neutral atoms is measured using photometric detectors

- Note: The excitation of neutral atoms is brought only by radiation from a hollow cathode lamp and not by the thermal energy of the flame.

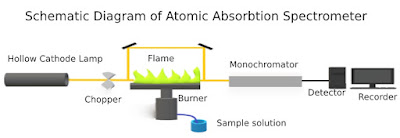

Instrumentation of Atomic Absorption Spectrometer

Hollow Cathode Lamp

- The source of light in AAS is a hollow cathode lamp.

- The cathode is made up of specific elements or alloys of elements on the cathode.

- when current is applied to anode and cathode, metal ions emerge from the collides with filler gas, which is argon. Due to these collisions, the number of metal atoms is excited and emit their characteristic radiation.

- This radiation is absorbed by neutral atoms of the same elements in the ground state, which occur in the flame when the sample solution is sprayed.

- The determination of every element, separate HCL has to be using multi-element lamps.

- Ex: Two elements lamps Na/K, Ca/Mg, Three elements lamps Ca/Mg/ Zn.

Burner

- There are different burners available, which are used to spray the sample solution into fie droplets and mix it with fuel and oxidant.

- The most common ones are the Total consumption burner and the Laminar flow burner.

Chopper

- The instrument had choppers, which rotate as fans allow alternatively radiation from flame alone or radiation from HCL and flame.

- This procedure is a pulsating current signal, which is used to measure the intensity of light absorbed by elements, without interference by radiation from the flame itself.

Monochromator

- To isolate the line spectrum of the element from the background signal of the flame. so a monochromator that can provide a good resolution of 1 nm is required.

Detector

- The intensity of radiation absorbed by elements, in the UV or Visible region (190-800 nm) can be detected phototube or a photomultiplier tube.

Recorder

- The recorder readout is capable of displaying absorption spectrum as well as absorbance at a specified wavelength.

Application of Atomic Absorption Spectrometer

- Atomic Absorption Spectrometer is mainly used for quantitative analysis of various elements present in different samples.

- Major of the applications are Agriculture, Forensic, Environmental, Food, Pharma, Mining, and petrochemical industries.

- Estimation of trace elements in biological fluids (ex: blood, urine etc).

- Estimation of elements like copper, Nickel and Zinc, Magnesium, Zinc, mercury, Lead etc.

- Estimation of elements in soil samples, water supply, effluent ceramics, etc.

SOP for Atomic Absorption Spectrometer

- Company Logo Company Name, Unit, Address, Area

TITLE: Operation and Calibration of Atomic Absorption Spectrometer

SOP No. QC-XX , Department: Quality Control Revision No.0.0.

Page No.xx of effective Date: xx. yy. zzzz Review Date: 3 yrs from the effective date

PURPOSE

- This procedure describes the Operation and Calibration of the Atomic Absorption Spectrometer

SCOPE

- This procedure is applicable to the QC departments at the Company name, Unit, and Address.

ABBREVIATIONS

- AAS: Atomic Absorption Spectrophotometer.

- FAAS: Flame Atomic Absorption Spectrophotometer.

- GFAAS: Graphite Furnace Atomic Absorption Spectrophotometer.

- VGA: Vapour Generation Accessory.

- Abs: Absorbance

- nm: Nanometer

- ppb: Parts per billion

- ppm: Parts per million

- RSD: Relative Standard Deviation

- NLT: Not Less Than.

- NMT: Not More Than

- QC: Quality control

- QA: Quality Assurance

RESPONSIBILITY

- Analysts/Users are responsible to follow this procedure.

- QC Manager / Designee is responsible for the implementation of this procedure.

- QA Manager / Designee shall monitor compliance with this procedure.

Safety Precautions

- Operate the spectrophotometer with the flame shield closed and the sample compartment front panel in place.

- Use the correct burner

head for different flame modes.

- Do not ignite flame

without burner head and nebulizer and also when the water level is too low in

the liquid trap.

- Do not use flammable solvent in or near the AAS which can create an explosion.

- Always use the correct

acetylene flow for Nitrous oxide – Acetylene mode.

- This mode will produce carbon deposits, making sure the extraction equipment above the instrument is working correctly.

- Always empty and clean

the liquid trap after completion of analysis.

- Never use a solvent having a weight per ml lower than 0.76.

Operation of Atomic Absorption Spectrometer

Flame Mode

- Switch on the instrument. Check all the tubings for gas leaks.

- Select the gas either the air-acetylene or nitrous oxide-acetylene as per the method.

- Place the hollow cathode lamp, mention the current and perform an optical set-up.

- Ignite the flame and allow it for a few minutes to stabilize.

- Carry out adjustments for flame height, gas flow rate and burner position to obtain maximum absorption signal. Ensure that a real-time graph is displayed.

- Aspirate deionized water and auto-zero the absorbance signal.

- Click the start icon followed by calibration and sequence.

GFAAS Mode

- Switch on the instrument. Check all gas leaks.

- Turn on the hollow cathode lamp, and/or perform an optical setup, and allow the lamp to warm up.Switch on the cooling water supply and argon gas with an exit pressure of 70 psi.

- Set furnace heat program.

- Choose the composition of the wash liquid to efficiently remove traces of the sample solutions from the capillary.

- Dilute nitric acid (approximately 1% v/v) will be suitable for many aqueous sample types.

- Autosampler capillary tip must be aligned with the cuvette injection hole before use.

- Set the Argon gas supply. Turn on the water supply.

VGA Mode

- Switch on the spectrophotometer and install the Hydride generator parts and connect.

- Turn on the hollow cathode lamp, perform an optical setup, and allow the lamp to warm up.

- Prepare the reagents, sample as required and place them in the containers

- Set the heating element and quartz tube on the burner head.

- Set the temperature for the hydride generator. Connect the Argon tubing.

- Define sequence and start analyzing.

Startup AAS Software

⇓

Turn on power

⇓

Run mode

⇓

Analysis

⇓

Initialization

⇓

Set the Element lamp, Select the element and Set the Element

Lamp

⇓

Peak search and wavelength scan

⇓

Set the instrumental parameters ( Optical and measure method )

⇓

Set the elemental measurement parameters

⇓

Optimize the atomizer position for furnace mode

⇓

Set the sample

⇓

Standard concentration set-up

⇓

Select the Correction Method, Curve equation, concentration

unit, sample

⇓

Select the measurement parameters and perform the measurement

Calibration of Atomic Absorption Spectrometer

Flame

System Sensitivity Check

- Measure 2.0 ppm Copper standard solution.

Acceptance Criteria:

- The average of seven

absorbance readings should be NLT 0.280 Abs&% RSD should be NMT 1.

Linearity in Flame Mode

- Perform Linearity with at least three calibration points for Zinc (213.9 nm), Copper (324.7 nm)and K (766.5 nm).

Acceptance Criteria: Regression should be NLT 0.99

GFAAS Sensitivity Check

- Measure 20 µL injection of 20 ppb Copper standard solution

Acceptance Criteria:

- The average of seven absorbance readings should be NLT 0.06 Abs & % RSD should be NMT 5.

- Perform Linearity with at least three calibration points for Lead (283.3 nm)

Acceptance Criteria:

Regression should be NLT 0.99

VGA MODE (Hydride Generator)

- Linearity: Perform Linearity with at least three calibration points for Mercury.

Acceptance Criteria:

Regression should be NLT 0.99.

Linearity in Flame Mode

- Perform Linearity with at least three calibration points for Copper (324.7 nm)Acceptance Criteria: Regression should be NLT 0.99

Linearity in GFAAS ModeLinearity:

- Perform Linearity with at least three calibration points for Mercury.Acceptance Criteria: Regression should be NLT 0.99Perform Linearity with at least three calibration points for Lead (283.3 nm)Acceptance Criteria: Regression should be NLT 0.99

VGA MODE (Hydride Generator)

- Calibration Frequency: Once in six months.

Maintenance:

- Check the exhaust system using the smoke.

- Check the acetylene cylinder pressure.

- Ensure that the acetylene is not drawn into the instrument.

- Inspect the gas hoses for any damage.

- Turn on the gas supplies to the instrument and check all hoses and connections for leaks.

- Check water connections for GFAAS operation. Check the burner for deposits.

- If any, soak with detergent and clean with distilled water.

- At frequent intervals inspect the inside of the graphite shroud which is mounted at the centre cooling block.

- Using a cotton bud or similar material, ensure that the bore and injection hole is free from loose carbon or sample residues.

REFERENCES

- AAS User Manual

REVISION HISTORY

- Version no. Effective date Summary of revision

0.0 xx. yy.zzzz New SOP

END OF THE DOCUMENT

Prepared by Reviewed

by Approved by

Name:

Designation: Executive-QC Manager-QC Manager-QA

Signature Date:

No comments:

Post a Comment

Don't post spam links